- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-07-25 Origin: Site

When I get questions about the melting point of stainless steel, I always point out the melting range sits between 1,400°C and 1,530°C (2,550°F–2,790°F). The melting point of stainless steel changes based on the grade. For example, 304 stainless steel melts at 1,400°C–1,450°C. This matters because the melting point helps me pick the right material for high-temperature jobs. I use this info for welding, casting, or picking metals for extreme environments. Here’s a quick look at some popular melting point ranges:

Stainless Steel Grade | Melting Range (°C) | Melting Range (°F) |

|---|---|---|

304 | 1400–1450 | 2552–2642 |

316 | 1375–1400 | 2507–2552 |

430 | 1425–1510 | 2597–2750 |

I find this melting point chart handy whenever I need to compare which stainless steel grade stands up best to heat.

Stainless steel melts within a range of about 1,400°C to 1,530°C, depending on its grade and alloy mix.

Different grades like 304, 316, and 430 have unique melting ranges that affect their heat resistance and best uses.

Elements like chromium raise the melting point and improve corrosion resistance, while nickel lowers the melting point slightly but adds stability.

Choosing the right stainless steel grade based on melting point helps prevent problems like warping or weld failure in high-heat jobs.

Stainless steel melts at much higher temperatures than metals like aluminum, making it ideal for tough, heat-exposed applications.

Image Source: pexels

Image Source: pexels

When I talk about the stainless steel melting point, I always start with the typical range. Most scientific sources agree that the melting point of stainless steel falls between 1,400°C and 1,530°C (2,550°F–2,790°F). This range comes from the way different alloying elements, like chromium and nickel, change the temperature where the metal starts to melt. I find this high melting point really useful. It means stainless steel can handle tough jobs in places like furnaces, engines, and other high-heat environments.

I often remind people that the melting point of stainless steel is not a single number. It’s a range because the metal is a mix of different elements. The exact temperature depends on the grade and the mix of metals inside.

Now, let’s get into the details. The melting point of stainless steel changes when you look at different grades. Each grade has its own recipe, so the melting range shifts a bit. I use this information when I need to pick the right material for a job that involves heat.

Here’s a table I use to compare the melting point range for some common grades of stainless steel:

Stainless Steel Grade | Melting Point Range (°C) | Melting Point Range (°F) | Melting Point Range (K) |

|---|---|---|---|

304 (Austenitic) | 1400 - 1450 | 2552 - 2642 | 1673 - 1723 |

316 (Austenitic) | 1375 - 1400 | 2507 - 2552 | 1648 - 1673 |

430 (Ferritic) | 1400 - 1510 | 2552 - 2750 | 1673 - 1783 |

I notice that 304 stainless steel, which I use a lot, melts between 1,400°C and 1,450°C. The melting point of 316 stainless steel is a bit lower, around 1,375°C to 1,400°C. Grade 430, which is ferritic, can go up to 1,510°C. These numbers help me decide which grade will work best when I need heat resistance.

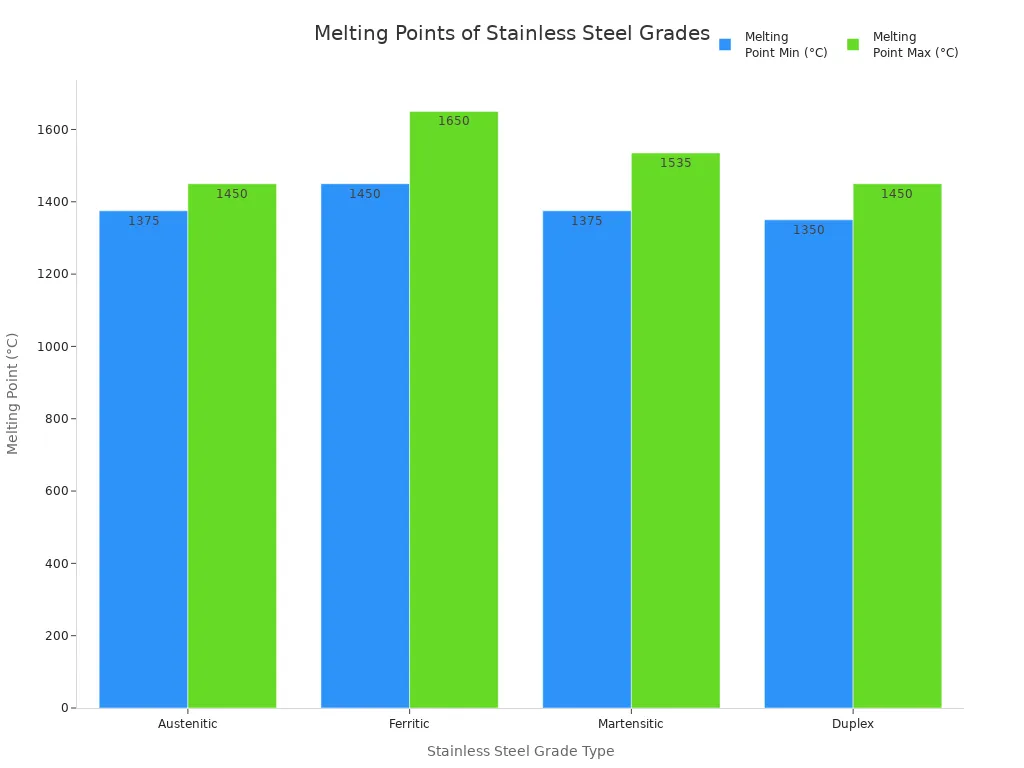

If you want to see how the melting point range compares across different types, check out this chart. It shows how austenitic, ferritic, martensitic, and duplex grades stack up:

I find it interesting that austenitic grades like 304 and 316 have a melting range that sits a bit lower than ferritic grades. Martensitic and duplex grades also have their own ranges. The melting point of stainless steel depends on the mix of elements and the crystal structure inside each grade.

When I look at international standards, I see that organizations like AISI and ISO don’t set a strict melting point for each grade. They focus more on the chemical makeup. The melting point data comes from the physical properties of each alloy, and it always reflects the influence of chromium, nickel, and sometimes molybdenum.

If you ever need to choose between common grades of stainless steel, always check the melting point range. It can make a big difference, especially if your project involves high temperature or heat treatment.

When I look at the stainless steel melting point, I always check the alloy composition first. The mix of elements inside stainless steel changes everything. Chromium and nickel play a big role. Chromium boosts corrosion resistance and helps keep the melting point high. Nickel makes the structure more stable and can lower the melting point a bit. I see this every time I compare different stainless steel alloys.

Here’s a quick table I use to remember how some elements affect the melting point:

Element | Effect on Melting Point | Effect on Corrosion Resistance |

|---|---|---|

Chromium | Raises | Increases |

Nickel | Lowers slightly | Increases |

Molybdenum | Raises | Increases |

Carbon | Lowers | Decreases |

I notice that the melting point of austenitic stainless steel sits lower than the melting point of ferritic stainless steel. Martensitic grades have their own range, and duplex grades fall somewhere in between. Precipitation hardening grades also show unique melting points. These differences come from the way each alloy is mixed.

I always remind myself: factors influencing the melting point include not just the main elements, but also trace amounts of others. Even small changes can shift the temperature where stainless steel starts to melt.

Crystal structure matters a lot for the stainless steel melting point. I see austenitic, ferritic, martensitic, duplex, and precipitation hardening types. Each one has a different arrangement of atoms. This changes how the metal reacts to heat.

Austenitic stainless steel has a face-centered cubic structure. It melts at a lower temperature compared to ferritic types.

Ferritic stainless steel uses a body-centered cubic structure. It usually has a higher melting point.

Martensitic stainless steel forms a body-centered tetragonal structure. Its melting point sits in a unique range.

Duplex stainless steel mixes austenitic and ferritic structures. Its melting point falls between the two.

Precipitation hardening stainless steel gets its strength from special heat treatment and its effect on melting point is noticeable.

When I use melting point measurement methods, I see these differences in action. The way atoms stack up changes how much heat the metal can take before it melts. I always consider heat treatment and its effect on melting point, especially when I need to pick a grade for high-temperature jobs. Temperature, corrosion resistance, and the right melting point measurement all matter when I work with stainless steel.

When I work with 304 stainless steel, I always pay close attention to its melting point. The melting point of 304 stainless steel sits between 1,400°C and 1,450°C (2,552°F–2,642°F). This range comes up again and again in my projects. I see it listed in technical charts and industry guides. It’s the number I keep in mind when I need a material that can handle serious heat.

I use 304 stainless steel because it’s reliable. It has about 18% chromium and 8% nickel. These elements help it stand up to high temperatures and resist corrosion. I find that the melting point of 304 stainless steel makes it a solid choice for many jobs. I never have to guess if it will hold up in the heat.

When I start comparing the melting points of 304 and 316 stainless steel, I notice some important differences. The melting point of 304 stainless steel is a bit higher than the melting point of 316 stainless steel. Here’s a table I use to keep things straight:

Property / Grade | 304 Stainless Steel | 316 Stainless Steel |

|---|---|---|

Melting Point | 1,400°C–1,450°C | Slightly lower (1,375°C–1,400°C) |

Max Service Temperature | 425°C–860°C | Up to 843°C |

Corrosion Resistance | Good | Superior (especially in acids) |

High-Temp Strength | Reduces with heat | Retains strength better |

I always tell people that 304 stainless steel can handle higher ultimate temperatures before it melts. But 316 stainless steel keeps its strength better when things get hot. When I’m comparing the melting points of 304 and 316 stainless steel, I look at more than just the numbers. I think about how each grade reacts to heat over time.

Here are a few things I keep in mind:

304 stainless steel has a higher melting point, but it loses strength and ductility above 427°C.

316 stainless steel holds up better at high temperatures because of its molybdenum content.

Both grades resist oxidation up to about 815°C, but 316 is more corrosion-resistant, especially in harsh environments.

304 is more likely to become sensitized between 427°C and 900°C, which can lower its corrosion resistance.

I choose 316 stainless steel for demanding, high-temperature jobs, even though its melting point is a bit lower.

So, when I’m comparing the melting points of 304 and 316 stainless steel, I don’t just look at the melting point. I also think about how each one performs under real-world heat.

I use 304 stainless steel in all sorts of high-temperature applications. Its melting point and thermal stability make it a favorite in many industries. I see it in chemical processing plants, food processing equipment, aerospace parts, oil and gas pipelines, and power generation systems. These places need materials that can take the heat and keep working.

Here’s a quick look at where I find 304 stainless steel most often:

Application Area | Why 304 Stainless Steel? |

|---|---|

Chemical Processing | Handles heat and resists corrosion |

Food Processing | Safe for food, stands up to cleaning and heat |

Aerospace | Lightweight, strong, and heat-resistant |

Oil & Gas | Survives high temps and tough environments |

Power Generation | Keeps strength at elevated temperatures |

I like that 304 stainless steel can work up to about 870°C (1,600°F) for short periods and up to 925°C for continuous use. The melting point of 304 stainless steel gives me confidence that it won’t fail when things get hot. The chromium and nickel inside help it resist scaling and keep its shape.

I always remind myself that using the wrong stainless steel grade can cause problems. If I pick a material with a lower melting point, I risk warping, cracking, or even burning through the metal. I’ve seen welds fail and parts deform when the heat goes beyond what the metal can handle. That’s why I stick with 304 stainless steel for jobs where heat resistance matters.

Image Source: pexels

Image Source: pexels

When I compare the melting point of steel in different forms, I notice some interesting differences. Both stainless steel and carbon steel can handle a lot of heat, but their melting points are not exactly the same. I often use this table to keep things clear:

Metal Type | Melting Point Range (°F) | Melting Point Range (°C) |

|---|---|---|

2500 – 2790 | 1371 – 1532 | |

Carbon Steel | 2600 – 2800 | 1425 – 1540 |

Carbon steel usually melts at a slightly higher temperature than stainless steel. The melting point of steel depends on its composition. Low carbon steel melts at the lower end, while high carbon steel can reach the top of the range. I find that the melting point of steel changes when I add elements like chromium or nickel. Stainless steel gets its strength and corrosion resistance from these additions, but sometimes this lowers the melting point just a bit.

I always check the melting point of steel before picking a material for high-heat jobs. Carbon steel works well for forging and casting, but stainless steel gives me better corrosion resistance and still handles high temperatures.

Now, let’s talk about aluminum. The melting point of steel, whether stainless or carbon, is much higher than aluminum’s. Here’s a quick comparison:

Metal | Melting Point (°C) | Melting Point (°F) |

|---|---|---|

Aluminum | ~660 | ~1220 |

Stainless Steel | 1400 – 1530 | 2550 – 2800 |

Aluminum melts at only about 660°C (1220°F). That’s less than half the temperature needed to melt stainless steel. I see this difference every time I work with these metals. Aluminum heats up and melts fast, so I have to watch my welding torch closely. The melting point of steel means it takes more energy to process, but it also means I can use it in places where aluminum would fail.

Stainless steel’s higher melting point lets me use it for exhaust systems, ovens, and engine parts.

Aluminum’s low melting point makes it easy to shape, but it can’t handle high heat.

The melting point of steel gives it an edge for cookware and industrial equipment.

I pick stainless steel when I need heat resistance and durability, even if it takes more effort to work with.

I always remember: the melting point of steel sets the limit for where I can use it. Stainless steel stands out when I need something tough that won’t melt under pressure.

When I work on stainless steel projects, I always pay close attention to the melting point measurement. It guides every step I take in fabrication and welding. I can’t just guess the temperature. If I go too high, I risk ruining the metal. If I stay too low, the weld won’t hold. Here’s what I keep in mind:

Welders like me need to heat stainless steel above its solidus temperature to create a proper molten pool.

I have to control the temperature carefully. Too much heat can cause hot cracking, warping, or even weak spots in the weld.

The melting point measurement helps me pick the right welding settings and filler materials.

Safety always comes first. I know the maximum temperature limit so I don’t push the metal past its breaking point.

The melting point is not a single number. It’s a range, and it changes based on the alloy mix. That’s why I check the grade before I start.

Many people think all steel melts at the same temperature. That’s not true. The importance of melting point in fabrication shows up when I switch between grades. I’ve seen engineers mix up melting point and softening temperature. That mistake can lead to bad welds or even accidents.

Tip: Always double-check the melting point range for your stainless steel grade before you start welding. It saves time and prevents costly errors.

I often get asked why the melting point matters for high-temperature application. The answer is simple. It tells me how much heat the metal can take before it fails. When I choose materials for ovens, engines, or chemical plants, I look at the high-temperature performance first.

Here’s a quick table I use to compare:

Application | Why Melting Point Matters |

|---|---|

Industrial ovens | Prevents warping or melting |

Exhaust systems | Handles constant high heat |

Power plants | Keeps strength under pressure |

Chemical reactors | Resists breakdown in extreme conditions |

The importance of melting point in fabrication and process planning can’t be ignored. I use this info to select the right stainless steel for each job. It helps me avoid failures and keeps everyone safe. I never assume the melting point is the same for every grade. I always check the numbers and plan my work around them.

I always check the melting point range before I pick a stainless steel grade. Here’s a quick table I use to see how melting points and alloying elements shape their uses:

Grade Type | Melting Point (°C) | Key Elements | Where I Use It |

|---|---|---|---|

Austenitic | 1400–1450 | High Ni, Cr | Chemical plants, high-temp corrosion |

Ferritic | 1425–1510 | High Cr, low Ni | Exhausts, heat exchangers |

When I select stainless steel, I always:

Match the melting point to the job’s heat needs

Watch for nickel or chromium content

Use accurate tools for temperature checks

Think about welding safety and material strength

Picking the right grade keeps my projects safe and strong.

If I heat stainless steel above its melting point, it turns into a liquid. The metal can lose its shape or even drip away. I always watch the temperature to avoid this.

No, I need to melt the edges a bit to join them. Welding works by creating a small molten pool. I use the right temperature to avoid burning through the metal.

No, it doesn’t. Different grades melt at different temperatures. Here’s a quick table I use:

Grade | Melting Point (°C) |

|---|---|

304 | 1400–1450 |

316 | 1375–1400 |

430 | 1425–1510 |

Stainless steel is a mix of metals. Each element melts at a different temperature. The blend creates a range instead of one exact number. I always check the grade before heating.

Yes, I use stainless steel pans and trays in my oven all the time. They handle normal baking temperatures easily. The melting point is much higher than any home oven can reach.