- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-04-01 Origin: Site

Ever wondered how to make stainless steel more durable and visually appealing? Ion-plated stainless steel is the solution. This advanced technique, known as PVD, bonds a layer of metal onto stainless steel, enhancing its strength and appearance.

In this post, we'll explore what ion-plated stainless steel is, how the process works, and its various benefits. You'll learn why it's a popular choice in many industries for its durability and cost-effectiveness.

Ion plating, also known as Physical Vapor Deposition (PVD), is a process used to coat stainless steel with a thin layer of metal. The process involves vaporizing the metal and using a vacuum chamber to deposit the vaporized particles onto the stainless steel surface. This creates a strong, durable bond between the metal and the base material.

Unlike traditional electroplating, which uses a liquid solution to deposit metal ions, ion plating involves vaporized metal particles. This results in a more uniform, harder coating with better wear resistance. PVD coatings are also more environmentally friendly, as they do not require harmful chemicals.

Ion-plated stainless steel is significantly stronger and more durable compared to traditional plating methods. The ion plating process creates a tight bond, making the metal more resistant to wear, scratches, and corrosion. This makes it ideal for use in high-contact applications, such as watches and automotive parts.

Ion plating offers an affordable alternative to more expensive metals like gold. Stainless steel, a cost-effective base material, helps reduce the overall cost while still delivering a high-quality, durable finish. It’s a great option for industries looking for a balance between quality and cost.

The glossy finish of ion-plated stainless steel gives it an attractive, high-end appearance. The process allows for various colors and sheens, making it versatile for different uses. Whether in industrial machinery or consumer products, the enhanced look of ion-plated stainless steel adds value to the final product.

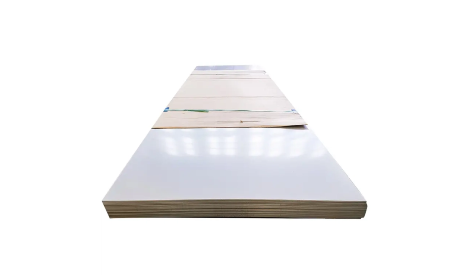

Stainless steel is an excellent material for ion plating due to its strength, corrosion resistance, and versatility. Stainless steel grades, like 316 stainless steel plate, 430 stainless steel plate, and 410 stainless steel plate, offer different benefits depending on the application.

316 Stainless Steel Plate: Known for its high resistance to corrosion, ideal for marine and chemical applications.

430 Stainless Steel Plate: Offers good corrosion resistance and is more affordable, making it suitable for general use.

410 Stainless Steel Plate: Provides high strength and hardness, often used in mechanical and industrial applications.

These properties make stainless steel an ideal candidate for ion plating, ensuring the final product is durable, cost-effective, and visually appealing.

Ion-plated stainless steel is a step up from regular stainless steel. The main difference lies in the coating. Ion plating adds a thin, durable metal layer that bonds to the surface, making it more resistant to scratches and corrosion. Regular stainless steel, while strong and durable, lacks this extra protective layer, which makes it more prone to wear and tarnishing over time.

The appearance of ion-plated stainless steel is also more polished and vibrant. Its glossy, metallic finish can be customized in different colors, giving it a premium look. Regular stainless steel typically has a matte or brushed finish, which, while appealing, may not offer the same level of visual enhancement.

When comparing ion-plated stainless steel and titanium, each has its advantages. Titanium is known for its lightness and exceptional strength-to-weight ratio, but it is more expensive. It also lacks the versatility in appearance that ion-plated stainless steel provides, such as the ability to create a shiny, colorful finish.

Ion-plated stainless steel, on the other hand, offers excellent durability at a more affordable price. It has superior corrosion resistance, especially when combined with high-quality grades like 316 stainless steel. In industrial applications where cost-effectiveness is crucial, ion-plated stainless steel is often preferred over titanium.

Different stainless steel plates, such as 303 stainless steel plate, 1/4 stainless steel plate, and 3/8 stainless steel plate, offer unique benefits depending on their intended use. Ion-plated stainless steel can enhance these base materials by adding a layer of metal that improves durability and appearance.

303 Stainless Steel Plate: Known for excellent machinability, often used in high-precision components. When ion-plated, it offers extra corrosion resistance.

1/4 Stainless Steel Plate: A thicker plate, ideal for heavy-duty industrial applications. Ion plating can improve its surface strength.

3/8 Stainless Steel Plate: Provides extra strength for structural use. Ion plating enhances its resistance to wear and environmental factors.

These stainless steel variations are ideal for ion plating, offering both aesthetic appeal and performance benefits in various industrial applications.

Ion-plated stainless steel is widely used in watches and electronic casings due to its strength and aesthetic appeal. The process creates a durable, scratch-resistant coating that withstands everyday wear. Watches, for example, are exposed to frequent handling, sweat, and moisture. Ion plating enhances both the durability and appearance, making the surface resistant to tarnishing and corrosion. The glossy finish also gives electronic casings a sleek, high-end look.

In the automotive industry, ion-plated stainless steel is used in parts that are exposed to harsh conditions. Components like trim, grills, and exhaust parts benefit from ion plating, which adds a protective layer against rust, scratches, and environmental wear. The enhanced durability helps maintain the appearance and performance of automotive parts over time, even in high-contact areas.

Ion-plated stainless steel is ideal for use in medical devices due to its excellent corrosion resistance and biocompatibility. Surgical instruments, dental equipment, and implants made from ion-plated stainless steel can withstand the harsh sterilization processes while maintaining their integrity. The process also prevents tarnishing and rusting, ensuring that the equipment remains clean and safe for use.

In industrial applications, ion-plated stainless steel is used in tools, machinery, and other high-performance equipment. The enhanced wear resistance and corrosion resistance provided by ion plating increase the longevity and reliability of these components. From heavy-duty machinery parts to precision tools, ion plating helps maintain performance and extend the lifespan of industrial products exposed to tough working conditions.

To keep ion-plated stainless steel looking its best, it’s important to clean it gently. Use a soft cloth or microfiber cloth to wipe the surface regularly, removing dirt and oils. For deeper cleaning, a mild soap solution and warm water work well. Gently scrub with a soft brush or cotton ball. Avoid using harsh chemicals or abrasive cloths, as these can damage the coating and leave scratches.

Ion-plated stainless steel is resistant, but it’s still important to avoid prolonged exposure to chemicals. Household cleaning agents, oils, and pollutants can affect the finish. For instance, perfumes, lotions, or industrial chemicals may weaken the coating over time. Always clean your components after they come into contact with such substances.

While ion-plated stainless steel is highly durable, physical wear and tear can still occur. Avoid rough handling or contact with abrasive surfaces, as these may scratch or damage the surface. When working with industrial equipment, ensure components are not exposed to unnecessary friction or impact, which could compromise the finish.

Proper storage is key to maintaining the appearance and durability of ion-plated stainless steel. Store components in a dry, cool place to avoid humidity and moisture, which can cause damage. For added protection, use soft pouches or cases to shield items from scratches. When possible, keep parts covered to prevent dust or debris buildup. Proper storage will help extend the lifespan and keep the finish looking fresh.

Ion-plated stainless steel is highly durable, but environmental factors can still affect its finish over time. Exposure to UV light, humidity, and chemicals can weaken the coating. For example, prolonged exposure to sunlight or harsh weather conditions can cause discoloration. Similarly, chemicals like chlorine, found in pools, can corrode the surface. Regular physical contact, such as handling or rubbing against rough surfaces, can also contribute to the fading process by causing scratches or abrasions.

The lifespan of ion-plated stainless steel largely depends on the conditions it is exposed to. In industrial applications, it can last several years under normal wear, maintaining its appearance and durability. However, regular maintenance can significantly extend the life of the plating. Cleaning the surface gently and avoiding exposure to harsh chemicals will help preserve its finish for a longer time. Proper care, such as storing items in dry, cool places and minimizing physical contact, ensures a longer-lasting ion-plated surface.

Ion-plated stainless steel offers outstanding durability, corrosion resistance, and aesthetic appeal for industrial, mechanical, and medical applications. Its cost-efficiency and performance make it a preferred choice for many industries. Whether for watches, automotive parts, or medical devices, ion-plated stainless steel provides long-lasting benefits.

Explore more about ion-plated stainless steel products on our website and make an informed decision for your next industrial or mechanical need.

A: Yes, ion-plated stainless steel is hypoallergenic, making it safe for use in medical devices and sensitive environments. The coating process ensures it does not cause irritation, making it a suitable choice for individuals with sensitive skin.

A: Yes, ion-plated stainless steel can be re-coated to restore its shine. This is necessary when the coating starts to fade due to wear. Re-coating can be done through the same ion plating process to refresh the finish.

A: Compared to finishes like brushed or polished stainless steel, ion plating offers superior durability and wear resistance. It provides a stronger, more uniform coating and is available in various colors, enhancing both appearance and longevity.

A: The growing demand for ion-plated stainless steel in industries is due to its cost-effectiveness, durability, and aesthetic appeal. Its combination of affordability, strength, and long-lasting performance makes it ideal for mechanical and industrial uses.